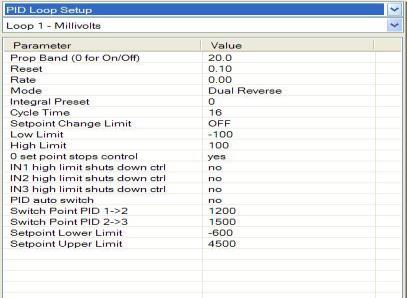

PID Loop Setup

PID is the tuning parameters entered for each Process Variable loop.

Prop Band (0 for On/Off)

This is the proportional band field. P = Proportional (Prop Band). This is a field in which you want to stay around the setpoint.

The range 0 – 999.0

Reset

This is the reset field. I = Integral (Reset). This is the actual temperature being monitored over a period of time and then averaged to keep within the Proportional band. The reset is in repeats per minute. This affects the output of the controller. It will be proportional to the amount of time the error is present. This helps to eliminate offset.

The range 0 – 100.00

Rate

This is the rate field. D = Derivative (Rate). This is the sudden change or rate in the temperature. This rate is in minutes. This affects the controller output which is proportional to the rate of change of the measurement and will control the amount of output by time restraints. Thus derivative takes action to inhibit more rapid changes of the measurement than proportional action. Derivative is often used to avoid overshoot.

The range is 0 – 100.00. The rate is not typically used for heating/carbon

Mode

This is the mode of the loop.

The values are: Dual Reverse, Single Reverse, Dual Direct, or Single Direct.

Dual – This has two output relays which can increase and decrease to achieve your SP.

Single – This has one relay which works in only one direction to achieve your SP.

Direct - If the PV - SP equals a positive number and the output would bring the PV down toward setpoint that is direct.

Reverse – If the PV - SP equals a negative number and the output would bring the PV up toward setpoint then that is reverse

Example: If a 12 mA output drives a 0 degree F temp. (PV) up to a 1200 degree F temp. (SP) this would be REVERSE and since this would take a SINGLE output from the controller the Mode for the Temperature Loop is Single Reverse.

Integral Preset

This field provides an offset for the starting point for PID control, also referred to as “Load Line” or “Manual Reset”. The range is –100 to 100.

Cycle Time

This field is typically set to the valve travel time multiplied by 1.5. The range is 0 – 300.

Setpoint Change Limit

This is a smart time feature that allows Process Loop to use PB only without Reset until the Process Variable drops below the percent output set under this category.

It is used to eliminate overshoot.

The Output percentage selected under this category must be above the normal operating output percentage of the furnace at heat.

Example – if the furnace runs at 40% output at heat for the maximum load, the setpoint change limit should be set to 60%.

The options are: OFF, 80 %, 70 %, 60 %, 50 %, 40 %, 30 %, or 20 %.

Low Limit

This is the low limit field. The range is –100 to 100.

High Limit

This is the high limit field. The range is –100 to 100.

0 Setpoint Stops Control

If the Setpoint is zero, then all outputs are turned off. The option is either Yes or No.

IN1 high limit shuts down ctrl

If input 1’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

IN2 high limit shuts down ctrl

If input 2’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

IN3 high limit shuts down ctrl

If input 3’s high limit is reached, then all outputs are turned off. The value can either be Yes or No.

PID Auto Switch

This is the PID auto switch field. The value can either be Yes or No.

Switch Point PID 1 -> 2

This is the PID Switch Point field. The range is –999 to 9999.

Switch Point PID 2 -> 3

This is the PID Switch Point field. The range is –999 to 9999.

Setpoint Lower Limit

This is the setpoint lower limit for the loop. The range is -999 to 9999.

Setpoint Upper Limit

This is the setpoint upper limit for the loop. The range is -999 to 9999.

*** For a list of the factory default settings for each PVT type, see Appendix A – PID Loop Factory Default Configurations. ***